One of the most important invention of mankind was the loom. A machine (powered by man till the industrial revolution) that could weave threads into a fabric.

We take fabric for granted nowadays but indeed it was an amazing feat to create it and invent the machine for producing it. Now, researchers at the MIT are taking the idea of loom one step forward: creating a fabric with very specific properties, and we have learnt in these last ten years that by using nanotechnology we can design materials with the physical characteristics we desire.

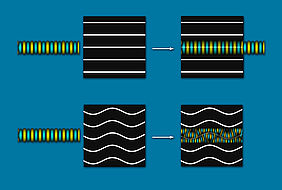

What they managed to do is to create a fabric as a set of layers separated by nano wrinkles that can selectively be transparent to certain wavelengths of light or sound. It is like having a cloth that will let only certain sound go through, or a certain colour!

More than that. The fabric can be modified in real time to change its "transparency" to certain wavelengths.

One application researchers are considering is to improve cancer diagnoses. In several cased cancer can be detected by using ultrasound but the problem with current ultrasound systems is the lack of resolution so that it is almost impossible to pinpoint a cancer in a soft tissue. Not so with this fabric. By changing its permeability to different sound waves it becomes possibile to increase the resolution and pinpoint the tumour area.

The researchers have developed this fabric first at the computer, simulating the characteristics they were looking for and then designing the nano-wrinkles to cease them.

We have really entered into a new dimension of creating artecraft: we can design not just their shape but also their physical properties by assembling bottom up the molecules.

ICT has entered into the creation of new products in a quite unexpected way and it will be even more so in the future. We are now (including in the "we" the EIT ICT LABS in its cyber-physical system area) entering the "industry 4.0", a industry where production is mediated by communicating robots, partly operating within a factorial, partly at the sale point and partly in the homes of the customers, but on the horizon we already see the "industry 5.0", the one where the fabrication material are designed at the computer to ensure the desired physical properties.